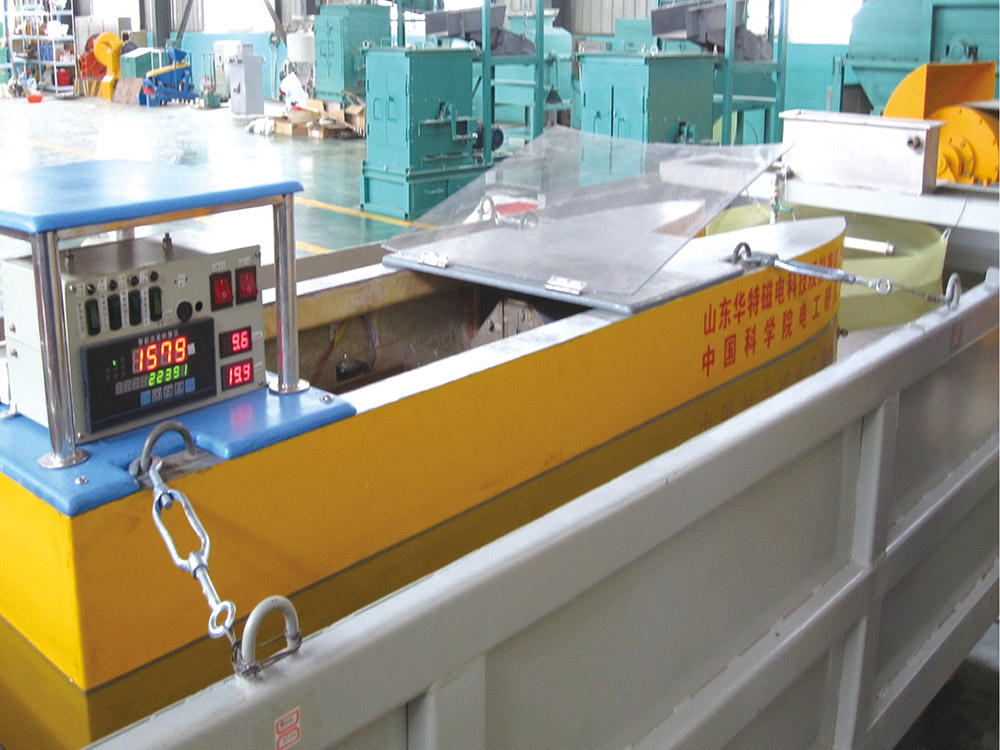

Seri CXJ Dry Powder Drum Pemisah Magnetik Permanen

Aplikasi

Mbusak polutan wesi saka powdery utawa bahan alus-grained.Iku digunakake kanggo dimurnèkaké mineral non-logam kayata bahan refractory, kaca, keramik, abrasives abrasive, etc.Chemical, gandum, lan non-magnetik logam ore impurity penghapusan, minangka uga pra-pilihan garing saka hematite lan limonite.

Karakteristik Teknis

◆ Dilengkapi feeder geter kanggo pakan seragam.

◆ Desain unik kanggo sirkuit magnetik lan sumber Magnetik digawe saka NdFeB kanthi kinerja dhuwur. Ambane permeabilitas magnetik gedhe lan nyedhot kuwat.

◆ Tipe anyar saka sistem magnetik kutub magnet sing ganti rugi, nyebabake kekuatan medan magnet sing luwih dhuwur lan kecerunan sing luwih gedhe.

◆ Sistem Magnetik multi kutub nambah jumlah kaping rolling materi Magnetik liwat lumahing drum, asil ing efek ngurutake luwih.

◆ Unit sakabèhé bebas pangopènan lan aman kanggo digunakake.

◆ Njabut impurities wesi saka materi wêdakakêna garing terus-terusan lan otomatis.

◆ Bisa digawe dadi rong utawa pirang-pirang drum.

◆ Ana macem-macem kekuatan medan magnet sing bisa dipilih (1000-7000Gs).

Parameter Teknis Utama

| Parameter/ Model/Item | ukuran (mm) | Drum dawa (mm) | Drum Diame (mm) | Magnetik Intensitas (Gs) | Drum No. | Drum Rotary kacepetan (r/min) | Kapasitas pangolahan (T/h) | Ukuran partikel (mm) | daya motor kw | |

| CXJ-40- Ⅰ | 550×460×660 | 400 | 300 | 1 | ≤0.6 | ≤5 | 0.55 | |||

| CXJ-60- Ⅰ | 830×710×930 | 600 | 400 | 1 | ≤1.5 | ≤5 | 0.75 | |||

| CXJ-60- Ⅱ | 1070×925×1240 | 600 | 320 | 2 | ≤2 | ≤5 | 1.5 | |||

| CXJ-60- Ⅲ | 1150×1070×1700 | 600 | 400 | 3 | ≤2.5 | ≤6 | 1.5 | |||

| CXJ-80- Ⅰ | 1180×820×1040 | 800 | 400 | 1 | ≤2 | ≤8 | 0.75 | |||

| CXJ-80- Ⅱ | 1420×1220×1570 | 800 | 400 | 2 | ≤2.5 | ≤8 | 1.5 | |||

| CXJ-80- Ⅲ | 1770×1260×1570 | 800 | 400 | 3 | ≤3 | ≤8 | 2.2 | |||

| CXJ-100- Ⅰ | 1300×1020×1240 | 1000 | 500 | 1 | Frekuensi variabel | ≤2.5 | ≤10 | 3 | ||

| CXJ-100- Ⅱ | 1620×1420×1770 | 1000 | 500 | 2 | luwes | ≤4 | ≤10 | 4 | ||

| CXJ-100- Ⅲ | 1970×1460×2309 | 1000 | 508 | 1000-7000 | 3 | ≤5.5 | ≤10 | 5.5 | ||

| CXJ Ⅱ -120- Ⅰ | 2006×1100×1450 | 1200 | 600 | 1 | ≤5 | ≤10 | 3 | |||

| CXJ Ⅱ -120- Ⅱ | 2274×1700×2250 | 1200 | 600 | 2 | 17-82 | ≤6 | ≤10 | 5.5 | ||

| CXJ Ⅱ -120- Ⅲ | 2880×1700×2950 | 1200 | 600 | 3 | ≤8 | ≤10 | 3×3 | |||

| CXJ Ⅱ -140- Ⅰ | 2206×1100×1450 | 1400 | 600 | 1 | ≤6 | ≤10 | 4 | |||

| CXJ Ⅱ -140- Ⅱ | 2274×2000×2250 | 1400 | 600 | 2 | ≤8 | ≤10 | 7.5 | |||

| CXJ Ⅱ -140- Ⅲ | 2800×2000×2850 | 1400 | 608 | 3 | ≤10 | ≤10 | 4×3 | |||

| CXJ Ⅱ -160- Ⅰ | 1960×1274×1650 | 1600 | 800 | 1 | ≤10 | ≤12 | 5.5 | |||

| CXJ Ⅱ -160- Ⅱ | 2674×2160×2850 | 1600 | 800 | 2 | ≤12 | ≤12 | 5.5×2 | |||

| CXJ Ⅱ -160- Ⅲ | 3120 × 2160 × 3700 | 1600 | 800 | 3 | ≤15 | ≤15 | 5.5×3 | |||